Brewing beer requires high-quality raw ingredients to produce delicious crafts— and do you know yeast is one? The same in making bread and wine, yeast plays a significant role in beer brewing.

Yeast gives the beer its distinct flavor, aroma, and fizz. Understanding what is yeast and its role in the beer brewing process is crucial.

What is Beer Yeast?

Yeast is an essential ingredient in beer brewing. During the yeast fermentation of the beer-making process, alcohol and carbon dioxide form as by-products; the formed carbon dioxide makes the beer fizzy. Yeast strains also help produce the flavor and aroma of the beer.

Different types of yeast strains produce other flavor profiles and aromas. Brewmasters must choose the type of yeast according to the recipe or style they want for their beer.

Types of Beer Yeast Strains

You can see different types of beer yeast strains, and each has unique properties that affect the beer fermentation flavor, aroma, and characteristics. Some common yeast strains that are used for beer brewing are:

1. Ale Yeast

Ale yeast (Saccharomyces cerevisiae) has been in the brewing history since the ancient civilization in Egypt and Mesopotamia. The discovery of the role of yeast in fermentation and its ability to isolate and cultivate individual yeast strains has marked a significant milestone in beer brewing.

Today, there are several strains are available that produce unique flavors and characteristics that allow brewers to create a wide variety of beer styles.

Fermentation Process of Ale Yeast

Part of the yeast fermentation process is all the same as how ale yeast strain works, they only differ with their temperature conditioning.

The fermentation process starts by adding the yeast to the cooled wort. Brewers provide oxygen to the mixture to make the yeast grow and reproduce, making oxygen their source of nutrients.

When the yeast is done with its aerobic phase, it starts on the anaerobic phase, where the oxygen depletes and the sugar fermentation produces alcohol and carbon dioxide as their by-products.

The process enters the primary fermentation, with rapid yeast growth and intense fermentation activity; alcohol and carbon dioxide is produced in this stage.

In the second fermentation, the yeast consumes the residual sugar slower. In the second fermentation, brewers will add other ingredients, such as hops or other yeast, to condition the beer further.

When the desired alcohol level is reached, the yeast begins to settle out of the beer until it reaches its desired level of carbonation and clarity.

In the fermentation process, several factors include the duration and temperature used. You will see other differences among the yeast strains further into this article.

2. Lager Yeast

Lager yeast (Saccharomyces pastorianus) has a relatively recent history compared to the other yeast strains used in beer brewing. You can track the history of lager yeast to the 19th Century when a new brewing style emerged in Europe.

It is believed that lager yeast is a hybrid of ale yeast and another yeast species (Saccharomyces eubayanus). The lager yeast can ferment the beer at cooler temperatures and produce a clean and crisp flavor profile, leading to its widespread popularity.

The development of refrigeration in the early 20th century furthered the growth of lager brewing industry, as manufacturers could produce consistently on a large scale.

Fermentation Process of Lager Yeast

Unlike ale fermentation, lager fermentation should take place at cooler temperatures. Brewers usually cool them between 5 and 55 degrees Celsius, resulting in a cleaner, smoother flavor profile.

3. Belgian Yeast

Belgian yeast is closely associated with the distinct and complex flavor of Belgian beers. Belgian beers were first brewed back in medieval monasteries in Belgium for sustenance and religious rituals.

These yeast strains are often referred to as “wild yeast,” as they are not domesticated or commercial yeast strains like those used in other beer styles.

In the 19th and 20th centuries, Belgian yeast became a key ingredient in the development of the Belgian brewing industry. The yeast is known to produce a wide range of fruity, spicy, and earthy flavors, which have become the defining characteristic of Belgian beer styles.

Today, Belgian yeast continues to play a crucial role in the production of Belgian beer and is used by brewers around the world to produce authentic Belgian-style beers. Belgian yeast strains are often considered some of the most flavorful and versatile in the world, making them a popular choice among craft brewers and home brewers alike.

Fermentation Process of Belgian Yeast

Belgian yeast strain is best fermented at lower temperatures. Its ideal temperature is between 15 and 25 degrees Celsius which produces beers with fruity, spicy, and earthy flavors.

4. Wheat Beer Yeast

Wheat beer yeast is a popular strain in Europe. German hefeweizen is its popular beer style that has been produced from several centuries back until now.

Beers that use wheat beer yeast strain have a distinct fruity flavor and aroma. But its recent development has produced spicy and floral flavors and aroma too, which has become one of its defining factors.

Fermentation Process of Wheat Beer Yeast

The fermentation process of wheat beer yeast is quite similar to the other yeast strains used in beer brewing, but there are a few key differences in the fermentation process that are only specific to the wheat beer yeast.

Wheat beer yeast strains are fermented at lower temperatures, usually between 15 and 25 degrees Celsius. Fermenting wheat beer yeast at a cooler rate helps produce a wide range of fruity, spicy, and floral flavors for the beer.

Take note of the key differences in fermenting these yeast strains because the flavor and aroma of beer heavily depend on the process.

Selecting Yeast for Beer Brewing

The quality of your beer solely depends on the type of yeast strain you use in the brewing process. There are factors you have to consider in choosing the yeast strain to use because it affects the alcohol tolerance, flavor profile, and appearance of your desired beer style.

Here are the considerations you have to check when selecting yeast:

- Beer style: Each yeast strains produce different appearance, flavor, and aroma during the fermentation process. Choose the yeast strain that achieves the characteristics of your desired beer style.

- Fermentation temperature: Each yeast has a different fermentation temperature requirement. Determine if you can provide its desired temperature range to achieve the beer style you want.

- Alcohol tolerance: Yeast strain should have the right level of alcohol tolerance to ensure the beer ferments completely without producing any stale or off-flavors.

- Flavor Profile: Yeast strains produce different aromas and flavors. You have to choose the right yeast to achieve the desired flavor profile you want for your beer.

- Availability: Some yeast strains are seasonal. You have to know its origin and time of the year. This is important to ensure that the yeast strain is readily available.

You have to carefully select the right yeast strain and control its fermentation condition to produce high-quality beers with consistent and desirable flavor and aroma.

Common Yeast Challenges in Beer Brewing

Yeast makes or breaks the process of beer brewing. Although yeast is an essential ingredient, it may bring several challenges during the brewing process that affect beer quality. Some of the yeast problems you may face in beer brewing are:

Inaccurate Record Keeping

Record keeping is crucial in yeast management. You must maintain a detailed and accurate yeast movement to know the yeast stage in the fermentation tank. Key factors in the records are:

- Yeast strain

- Original pitch or received date

- Volume

- Viability

- Cell density

- Brand or batch harvested from

- Brand or batch pitching into

- Tank harvested from

- Tank pitched into

Detailed and proper fermentation records not only help you avoid beer fermentation problems but also helps predict seasonal yeast demand.

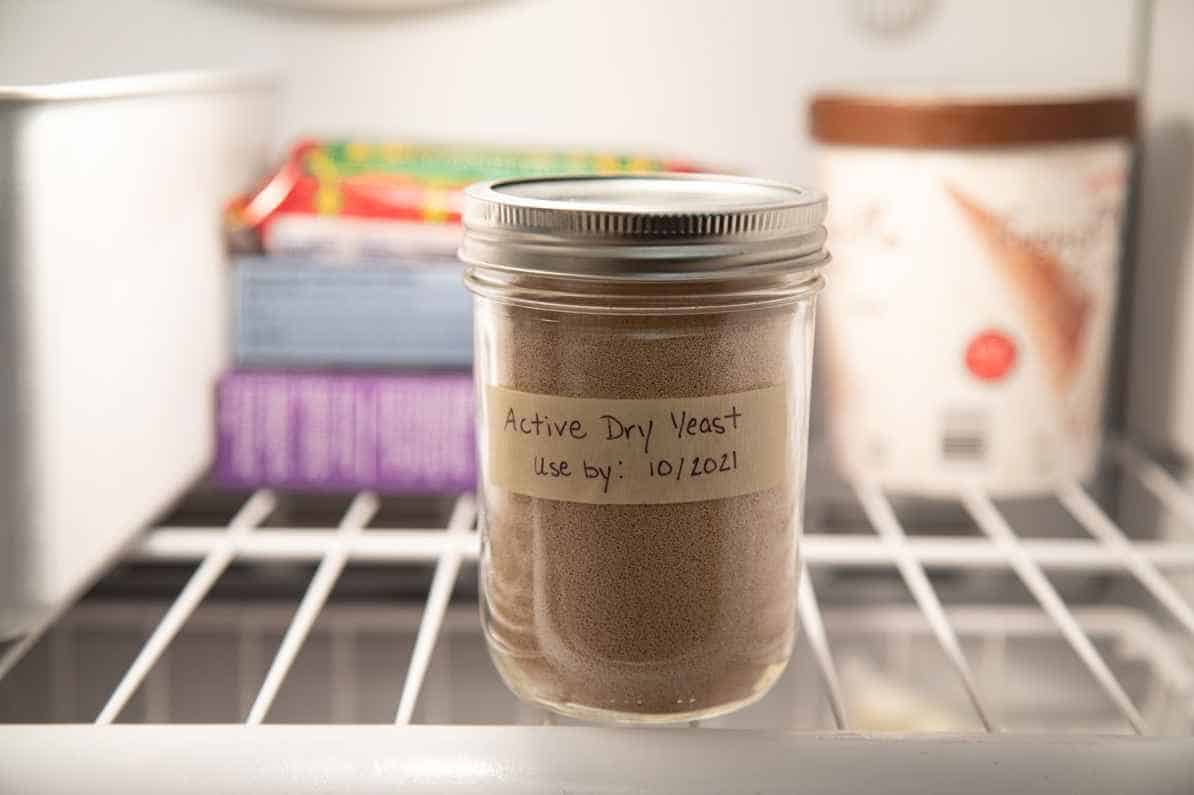

Improper Storage

Improper yeast storage results in spoilage. Properly store the yeast in a sealed sterile container and place it in a cool place. Make sure the container does not have any air to avoid yeast growth.

Cross-Contamination of Yeast Strains

Sanitation is crucial in the process of brewing beer. Yeast crosses production lines after brewing. After each batch, cleaning the equipment and pipes with the CIP/SIP system is necessary to ensure there are no yeast residues in the tank.

It may be time-consuming to check all the possible surfaces where the yeast may have come in contact, but a small amount of unnoticed yeast strain may affect the beer flavor.

Several Generations

Yeast strains continuously renew, and in each renewal, genetic changes happen. This change may affect the flavor characteristics, viability, flocculation capacity, and decay rate of the yeast.

It is essential for brewers to carefully manage yeast health and maintain good sanitation practices to avoid spoilage. Addressing these yeast challenges will produce high-quality beers with consistent yeast-derived flavors and aromas.

Final Takeaway

Yeast is a vital component in beer making. Understanding the role of yeast in beer brewing is only a part of what you need to learn; knowing its types and considerations help you create the beer style that you want. So, if you are planning to try out home beer brewing, you are on the right track.

As a homebrewer, Michael would get frustrated about the lack of brewing information on the internet. After hundreds of gallons of spoilt batches, Micheal had enough. And he founded Unknown Brewing as a resource for homebrewers.