What is Krausen? Well, you might know it by another name: fermentation foam! When making beer, you may have noticed a gang of bubbles congregating on top of your beer during fermentation. This frothy formation is what we call Krausen, and it’s formed during fermentation.

So, Krausen is the foam that forms during fermentation. Big deal, why should we care?

Krausen is an indicator of active fermentation. It also serves as a protective layer between your brewing beer and the oxygen in the air. And sometimes, it can also play a role in beer flavor.

Yes, Krausen does all these good things. But you must be aware of the issues that may arise with Krausen. And that’s where this article comes in. But before we get into all of that…

What is Krausen?

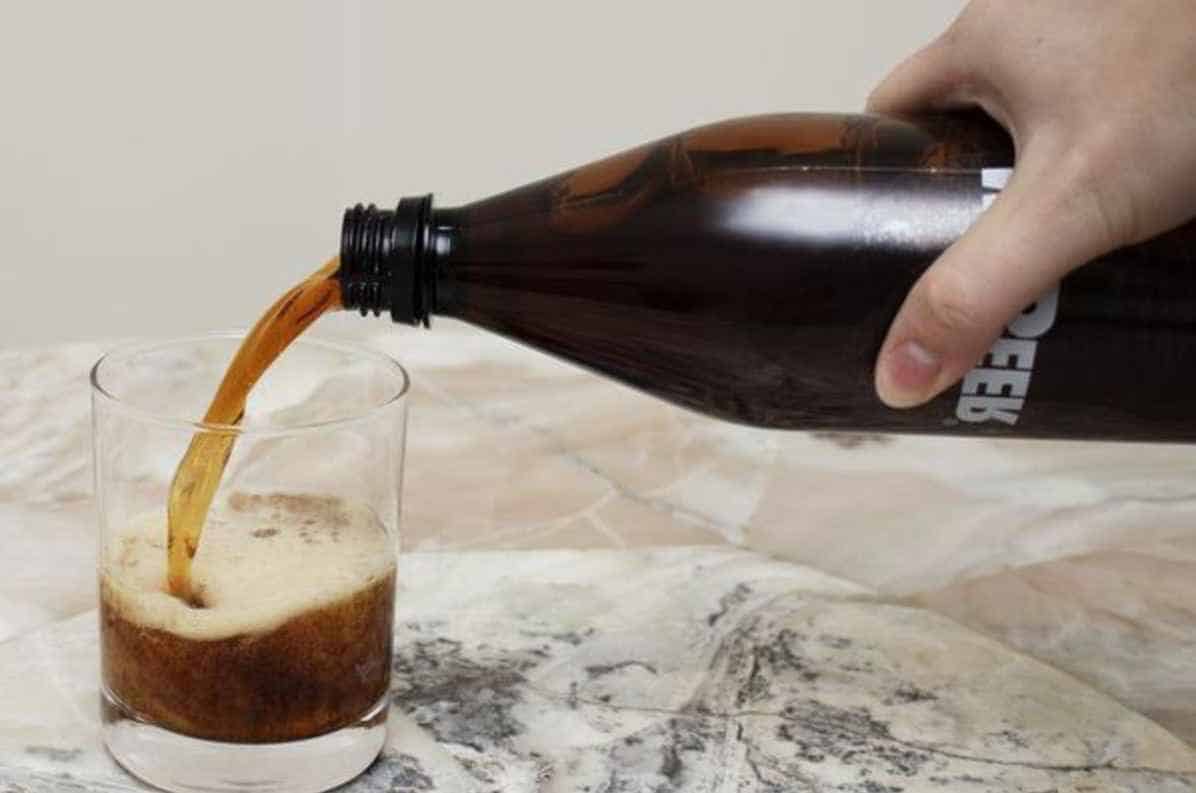

Krausen (which is pronounced as kroy-ZEN) is a brewing term that describes the layer of thick foam that occurs at the top of the beer during primary fermentation. Krausen is the result of yeast action on sugar. But how exactly does it form?

The Science Behind Krausen Formation

Carbon dioxide (which is one of the byproducts of fermentation) bubbles through the beer, collecting all manner of proteins. Eventually, the bubble ends up at the top of the fermenting wort, creating this brownish froth that we call Krausen.

But if Krausen is just a bunch of bubbles, why does it look so grimy and greasy?

As the carbon dioxide bubbles rise to the top, they collect all sorts of proteins, yeast cells, and hop resin. These compounds form complex bonds that encapsulate the CO2 bubbles, containing carbon dioxide gas for longer. These yeast cells, hop resin, and proteins give Krausen its grimy and dirty appearance.

The Role of Krausen in Fermentation

Though it may look grimy, dirty, greasy, or yucky, Krausen isn’t the bad guy. You’ll be surprised how helpful Krausen is brewing. But rather than sing its praises all day, why don’t we look at the role of Krausen in fermentation?

It Indicates Active Fermentation

This one’s straightforward, but I’ll still explain it. During fermentation, yeast converts sugar to alcohol and carbon dioxide gas. The gas bubbles to the top beer to form Krausen. Without fermentation, there would be no carbon dioxide. And without carbon dioxide, there would be no Krausen. No fermentation, no Krausen.

Krausen Improves Yeast Action

The CO2 bubbles that make Krausen are coated with proteins, hop resin, and yeast cells. Let’s back up a bit. Yeast cells have a tendency to clump with one another. And when this union happens, the yeast cells tend to sink to the bottom.

Clumping yeast cells are a problem because they interact with each other instead of working on the wort. And if left unchecked, issues like incomplete or slow fermentation may arise.

What is the role of Krausen in all this? As carbon dioxide bubbles through the wort, it picks up some yeast cells and takes them to the top. While at the summit, the yeast cells can get on with their job without the risk of clumping.

Oxidation Protection

In beer brewing, oxygen is the enemy. It can spoil the flavor of your brew and shorten the shelf life of your beer. But fermentation occurs in an airtight vessel; how does oxygen get in? One word; headspace.

When you transfer your wort to your secondary fermentor, there’s usually a space left between the wort and the lid. This space is filled with air, and we refer to it as the headspace.

Krausen floats to the top of the brewing beer, creating a buffer zone between your beer and the air. Krausen is like no man’s land between conflicting nations; beer and oxygen.

Promote Flavor Development

Yes, Krausen has an effect on beer flavor. But how?

The bubbles that make up Krausen are coated with hop resin, among other things. Hop resins can affect beer flavor and beer aroma. Hop resins contain various essential oils that are responsible for floral, spicy, and fruity characteristics.

Krausen Management

Often times as a brewer, you experience a blowout. This means that the Krausen has grown so large that it has clogged your airlock.

In such a situation, the built-up pressure within the fermentation vessel has no option but to blow out the airlock or pop the lid open. And let me not get into what could happen if oxygen and other contaminants gained access to your beer.

From what you can gather so far, Krausen is good, but too much of it is bad. How do we manage Krausen?

1. Choose the Right Fermentation Vessel

You want a fermentor with a wide neck (think bucket fermentor). The wide neck gives Krausen a larger surface to spread out. The wider the space it has to play, the lower the risk of a blowout.

2. Employ Effective Temperature Control Techniques

Besides carbon dioxide, heat is another byproduct of fermentation. Fermentation temperature can rise fast, depending on the amount of wort. For example, the temperature in a 5-gallon setup can increase by 10-15°F.

Yeast tends to work faster in warm conditions. Fast-acting yeast means lots of Krausen. And eventually, boom! Blowout.

You can prevent a blowout by keeping to optimal fermentation temperatures. And you can do this by using effective temperature control methods. Fermentation chambers are the ultimate temperature control gizmos. And you can find out all about them in this ultimate guide to fermentation chambers.

3. Remove Excess Krausen

Another effective method of preventing a blowout is (drumroll please) removing the excess Krausen. You can’t have a blowout when you keep scooping out the Krausen. This method is so effective that commercial breweries use it. Now, that’s a significant job in breweries; Krausen Scooper.

4. Use Blow-Off Tubes

A blow-off tube is a hose assembly that directs overflowing Krausen out of the fermentation vessel to an auxiliary vessel. It sort of functions like an airlock, but on a larger scale. It does not clog or get blown off.

To assemble a blow-off tube, you’ll need a hose and a cork stopper. A racking cane can also work. Fit the hose into the cork stopper and install it on your fermentation vessel. Insert the other end of the hose into an empty vessel. Congratulations, you’ve now got a blow-off tube.

But below is a video that could help you out.

Video Source:

5. Use a Krausen Kollar

A Krausen Kollar is a plastic sleeve that you fit on the neck of your fermenting vessel. Krausen Kollars are mostly used with bucket fermentors and they slip into each other like a ring on a finger.

Krausen Kollars work by increasing the headspace of your fermentation setup. They give you more time before a potential blowout, and they keep things tidy. Want to know how to use a Krausen Kollar? Check out the video below.

Video Source:

Krausen in Different Beer Styles

Does Krausen behave differently across different beer styles? Besides varying in behavior, Krausen varies in appearance across different beer styles. Well, let’s get into it.

- Krausen in German Hefewizens: German Hefeweizen Krausen (ooh, that rhymes) is thick and creamy, and for good reason. The yeast used in this beer style produces a lot of foam, creating this thick, pillowy Krausen on the beer. The Krausen has a distinct banana and clove aroma. Just thinking about it gives me the cravings.

- Krausen in Belgian Saisons: Belgian Saisons are often fermented at high temperatures. And you know what high temperatures do to fermentation. They result in more yeast activity and more Krausen formation. The Krausen in this beer style is often frothy and loose.

- Krausen in English Bitter: Krausen behavior in English Bitters is completely opposite from what we saw in Belgian Saisons. English Bitters ferment at cooler temperatures. This beer style is synonymous with slow fermentation and a less pronounced Krausen. The Krausen in this style is thin and compact, with a fine, creamy texture.

- Krausen in American IPA: American IPAs are known for their intense hoppiness. Since Krausen bubbles are coated with hop resins, the Krausen in American IPAs has a strong resinous hop aroma. They are thick and sticky too. If you look at the Krausen carefully, you can see visible hop particles.

Krausen and Carbonation

What is the relationship between Krausen and Carbonation? The most obvious relationship is that both result from the same brewing process (fermentation). But there’s another relationship that most of us don’t see; Krausen and carbonation work together to make our beer great. Let me explain.

By now, you must be getting tired of this story; yeast consumes sugar to produce alcohol and carbon dioxide gas. Initially, the carbon dioxide gas does not dissolve in the beer. So it bubbles and floats to the top to form Krausen.

As the Krausen grows, it expels the air in the headspace. And when that is done, the pressure within the fermentation vessel increases, and things start to change.

As the yeast continues its job, more and more carbon dioxide is produced. But now there’s high pressure in the vessel. The high pressure compels the CO2 gas to dissolve in the beer, therefore carbonating it.

Krausen enhances carbonation. Its growth increases pressure in the fermentor, forcefully dissolving carbon dioxide in your beer.

Final Thoughts

And that, amigos, is everything you need to know about Krausen. Pronounced as “Kroy-ZEN,” Krausen is the foam that forms on top of your wort in the fermentation phase of brewing. Krausen plays many roles in fermentation, including:

- Protecting your brewing beer from oxidation

- Promotes flavor development

- Promotes carbonation

Blowouts are messy and frustrating, I know. But as you scoop out the excess Krausen from your fermentor, look at the tiny bubbles and thank them for a job well done.

As a homebrewer, Michael would get frustrated about the lack of brewing information on the internet. After hundreds of gallons of spoilt batches, Micheal had enough. And he founded Unknown Brewing as a resource for homebrewers.