When you are in the brewing business, you might come across many terms. Pressurized fermentation might be one of them.

You might even be already practicing it. In starting and trying this process, you need to know the basics and factors included in the process. Here’s a pressurized fermentation guide to help you begin your journey.

The Process of Pressurized Fermentation

The world of beverages has always included fermentation. Fermentation has been present in some of the most popular drinks around the globe, like beers and wines. Through fermentation, beer takes on its irresistible taste and characteristic alcoholic kick.

This crucial chemical process has been present in the brewing industry for centuries. Still, it exists to create delicious beverages enjoyed worldwide. And so, what happens during a pressurized fermentation process?

What to prepare:

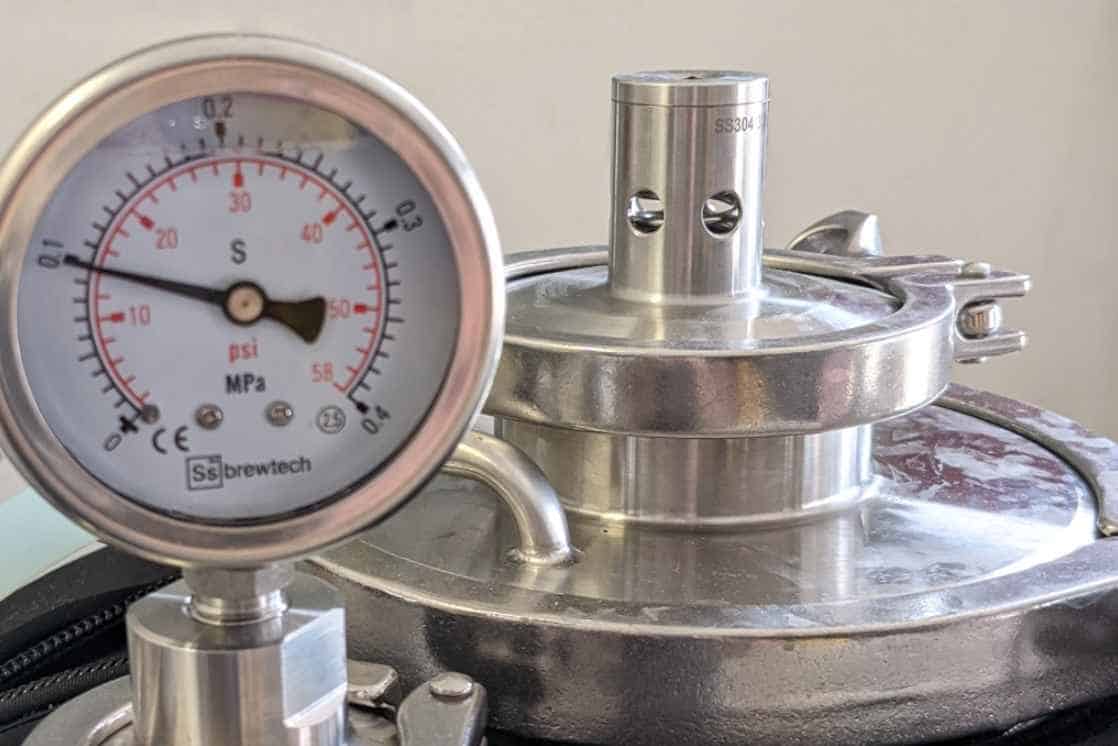

- Pressure-capable fermenter. This container should have the strength to withstand a pressure of up to thirty pounds per square inch.

- Pressure control tool or equipment

Steps:

- For a more efficient process, consider substituting the airlock with tubing from Spunding Valve into a blow-off. This way, you won’t have to keep swapping out the airlock during fermentation. Then, you can proceed with the fermentation as you would.

- Once the fermentation process has begun, adjust your Spunding Valve. See to it that it reaches your desired pressure, and let your beer start brewing.

Pressure fermenting is a surprisingly straightforward process. It’s easy to learn and get used to. With the right tools and equipment, you’ll be on your way to brewing some of the best beverages.

Basics of Pressurized Fermentation

Pressure

One of the critical components of pressurized fermentation is applying pressure, of course. In pressurized fermentation, ‘pressure’ refers to the pressure cranked up to create an intense environment within the vessel. The heightened atmosphere helps make the whole process possible.

Crafting homebrewed beer often takes a while. Pressure fermentation, however, can reduce a significant amount of the entire process.

Aiming for 10-12 PSI is perfect. However, experts recommend staying within 15 PSI if you want optimal results in as little as 24 – 48 hours. It’s important to note that not all yeast perform well under this brewing process. So, you should get to know your yeast first.

Fermentation

Fermentation is the primary process of making beverages like wines and beers. This process is critical to producing alcohol by converting glucose into ethyl.

Fermentation is also responsible for the carbonation of specific drinks. The fizzle adds to the fun component of drinking beers or sparkling wines. And, of course, the alcohol content spices up the drink and the occasion in general.

Equipment

To ensure a smooth process, you would need to find the necessary equipment to go through with the process.

- Container – For a kickstart, you would need to find a container or a vessel that’s resilient to pressure. Meaning that this container can withstand the procedure (intense pressure). Most standard vessels won’t cut it. You’ll need something more rugged, like a keg. Many types of barrels in all shapes and sizes are available in the market. Still, it’s good to look into the details indicated when you get the keg. This way, you also prevent yourself from extra costs.

- Spunding Valve – A Spunding Valve can control and maintain your desired pressure level. While most brewing tanks come equipped with Pressure Relief Valves (PRVs), they should only be there for emergency measures. It’s time to let a specialized valve take care of all your pressurizing needs. This tool allows brewers to customize and adjust their beer’s carbonation levels.

Benefits of Pressurized Fermentation

Pressurized fermentation is famous for a reason. Many brewers worldwide are learning about this process because it has a unique contribution to flavor. It adds up to many things a brew can offer. They continue making new and different beers for their customers as they progress.

No off-flavors

Brewing with pressurized fermentation lets you explore flavors without compromising quality. In other words, this process offers a door for more flavors to enjoy. These include bold beers full of flavor and character made at warm temperatures.

Factors out oxidation risks

During pressurized fermentation, the vessel is sealed off. This situation restricts oxygen from entering, thereby minimizing oxidation reactions. This helps protect flavor complexity and encourages more reliable yeast growth. These factors add to a more secure and tasty flavor in the beverage.

Faster process

Pressure fermentation allows for accelerated and more efficient production. Brewers can reduce their brewing time by fermenting under pressure.

Natural Carbonation

Fermenting under pressure allows for natural carbonation using a spunding valve. This process results in an efficient process that yields bubbly brews.

Get ready for faster fermentation and happier taste buds. With this method, the freshest beer is just around the corner. This also means you won’t have to undergo an extra process in attempts to carbonate your beer.

A better emphasis on hop flavor

Hops are an essential component and one of the base ingredients of beers. And so, they are responsible for quite a big part in the flavor formation of the beverage.

With pressure fermentation, you don’t have to worry about sacrificing your hops’ unique flavors and aromas. The air-tight system ensures that everything stays securely contained. The process derives a more robust beer.

Of course, choosing your beer is still according to your preference. Pressure fermentation is yet another process opening up more options for beer enjoyers. On this note, not every beer type is compatible with this process. There are specific types of beer that could end up tastier when pressure fermented.

Beers Suitable for Pressurized Fermentation

Lagers

Lagers offer a refreshing and smooth taste. This is because pressure fermentation cuts the process short. The yeast used in making these types of beer allows for higher pressure than other types of yeast.

Fermenting under pressure gives brewers the cleanness of a traditional lager with the full-bodied flavor and speed of an ale. This method does not have adverse side effects to lager too. And so you can still expect no off flavors and only enhancements to the beverage.

German-style beers

German-style beers, which are fizzle-filled drinks, can also benefit from this process. The process offers natural carbonation, and brewers prefer it to be as natural as possible. In this case, pressure fermentation is an excellent option.

IPAs

For IPAs, it’s really up to the drinker’s preference. With pressure fermentation, you can up your brewing game by giving your beer an intense hop flavor. However, some drinkers may prefer something other than the intense or extra hop flavor. This process also offers bolder aromas in every sip.

FAQs About Pressurized Fermentation

What does pressure contribute to fermentation?

Fermenting under pressure presents several effects on a beverage. It reduces undesired off-flavors and allows for faster and cleaner fermentation. The temperatures warmer than usual also contributes flavor.

The process also provides an extra effect on the beverage’s carbonation. This process helps craft unique beers at higher temperatures without compromising taste.

Is a spunding valve necessary in pressure fermentation?

To ensure the safety of your homebrew, adding a spunding valve and a pressure relief valve is vital. These elements also avoid any points of malfunction. A PRV alone can put your fermenter at risk. However, with this clever pairing, you’re protected from any unexpected pressure spikes.

What is the shelf life of a beer in a pressure fermenter?

Ensure that you bottle your beer within 24 days. Prolonging increases the chances of the beverages developing off flavors or even infection. While it can usually go longer than three weeks, it’s best to play safe and avoid wasting a good brew.

What is the recommended temperature when pressure fermenting?

This process offers a different approach to brewers rather than cold-fermenting. The mixture can start with the process at temperatures around 65 – 68F. This range gives brewers more control over their beers. It also allows for a more customized flavor depending on the target profile.

Is pressure fermentation a better process?

Pressure fermentation is not a one-size-fits-all situation. Other types of yeast respond well to pressure fermentation, but some are incompatible. Finding a yeast that works well with the pressurized fermentation process is best.

What’s the matter with fermenting at a higher temperature?

Warmer fermentation temperatures can induce rapid metabolic activity in yeast. And so this can result in unwanted flavors and aromas.

The pressure then counters these ‘unwanted’ flavors. This is why pressure fermentation is a great process to remove off-tastes in beers. It’s also an ideal way to achieve a more diverse flavor profile.

Summary

Apart from knowing the liquid or mixture you are working with, you should also be familiar with the processes.

You need to know the effects of it on the drink, so you can visualize and look into the flavor and texture it can offer. With this pressurized fermentation guide, you can now give it a shot with expectations of good taste.

As a homebrewer, Michael would get frustrated about the lack of brewing information on the internet. After hundreds of gallons of spoilt batches, Micheal had enough. And he founded Unknown Brewing as a resource for homebrewers.