Extra Special Bitter, or ESB, is an English-style ale famous for its intense hoppy flavor. This beer style walks a fine line between malt sweetness and hop bitterness.

With an alcohol content range between 5% and 6% ABV, it is the strongest of the British Bitters. The other beer styles in this category include the Ordinary Bitter (<4% ABV) and the Special Bitter (4-5%).

This article keenly examines the Extra Special Bitter and how to brew it. But before we get into the specifics, below is an overview of the ESB beer style:

| Color Range | 5-16 SRM |

| Original Gravity | 1.048-1.060 OG |

| Final Gravity | 1.010-1.016 FG |

| IBU Range | 20-50 IBU |

| ABV Range | 5-6% ABV |

| Appearance | Ranges from copper to amber-brown with superb clarity |

| Aroma | Moderate to none caramel aroma.

Moderate to high fruity aroma. |

| Flavor | Medium to high hop bitterness

Medium to high malt sweetness |

| Mouthfeel | Medium body with low carbonation |

| Serving & Storage Temperature | Glassware: Nonic Pint Glass

Serving Temperature: 50-55°F |

| Shelf Life | 3-4 months |

| Food Pairings | Meal Pairings: Fish & chips, roasted chicken |

| Cheese Pairings: English-Style Cheeses | |

| Dessert Pairings: Maple Bread Pudding |

Ingredients

The success of any brew is dependent on the quality of your ingredients. Below is a breakdown of the elements that make an Extra Special Bitter:

Water Treatment

Water makes up about 95% of beer. And as the most abundant component of beer, water influences the flavor and taste of the final brew.

For example, water quality determines the flavor of your wort. Water pH can also impact the perceived bitterness of your brew. And also, water contaminants like chlorine can result in off flavors.

The success of your brewing process depends on how you treat your water. But what water treatment techniques should you employ when brewing an Extra Special Bitter (ESB)?

In brewing, five ions boost the flavor of your ESB beer. These ions include Chloride (Cl-), Calcium (Ca2+), Magnesium (Mg2+), Sulphate (SO₄²-), and Sodium (Na+). As brewers, we use different salts to extract these ions. These salts include Epsom salt, gypsum, and sodium chloride.

Check out this article for more information on water adjustment.

Malt Selection

Malt is the chief source of fermentable sugars and protein. While fermentable sugars determine the alcohol content of beer, protein influences beer’s body and head.

The Extra Special Bitter is an English-style ale. As such, it requires a base of the finest British malts. And it doesn’t get any finer or more British than the Marris Otter malt.

Since we’ll be shooting for an original gravity of 1.059 OG, Marris Otter will make 87% of our grain bill. Any percentage around or above 80% is acceptable.

We’ll also use Crystal 80 and English Brown malts at 9% and 4%, respectively. While Crystal 80 malt imparts a mild yet balanced toffee flavor, English Brown malt is responsible for toasty and bready characteristics.

Hop Selection

Hops impart both bitterness and flavor. For bittering, we’ll use Fuggle hops. Extra Special Bitter beer style allows for up to 50 IBU. A 60-minute boil of Fuggle hops can impart a bitterness of about 33 IBU. As for flavoring, we’ll use East Kent Goldings.

Yeast Selection

There are a lot of suitable British yeast types that you can use to brew the Extra Special Bitter. For our demonstration, we’ll be using the London Ale Yeast. However, you can also use the following liquid and dry yeast varieties:

- Wyeast London (liquid)

- Fermentis S-04 (dry)

- Lallemand London ESB (dry)

Equipment

For the brew-in-a-bag (BIAB) technique, you’ll need the following:

- A grain mill (alternatively, you can buy already-crushed malt)

- A 20-gallon Brew Kettle

- 1 Brew Bag or Mash Basket

- 1 Hop Basket

- 1 Fermenter

- 1 pH Meter

- 1 Hydrometer

- Some Sanitizing Solution

Video Source:

Step-by-Step Brewing Process

After gathering your ingredients, the next step is to start your brew. Below is a step-by-step breakdown of the ESB brewing process.

Prepping Your Ingredients

Every brewing process starts with a little prep work. In our case, we’ll be prepping our brewing equipment, malt, and water ingredients.

Before starting any brew, you must sanitize or sterilize all your brewing equipment. You can sterilize your silicone hoses and racking cane by cooking them in boiling water for 10 minutes. As for the large brewing equipment like kettles and fermenters, you can wash them with some sanitizer.

The malt prep work involves milling our base and specialty malts. Milling involves crushing our grains into coarse particles called grist. Milling is vital because it increases the surface area for enzymatic action.

For this recipe, the grain bill comprises 87% Maris Otter malt, 9% Crystal 80 malt, and 4% English Brown malt. Measure out five pounds of Maris Otter malt, eight ounces of Crystal 80, and four ounces of English Brown malt. Mix the malts and feed them into your grain mill.

While owning a grain mill is convenient, it isn’t necessary. Alternatively, you can buy already-milled grains from your local homebrew store.

Prepping the water involves dispelling chlorine and adding water salts. To dispel chlorine, add 25mg of potassium metabisulfite for every gallon of water. Water salts include Epsom salt, gypsum, and sodium chloride.

Below is a table comparing the contribution of different water salts to the brewing process.

| Water Salt | Chemical Name and Formula | Contribution |

| Epsom Salt | Magnesium Sulphate (MgSO₄) | Source of Magnesium and Sulphate ions |

| Table Salt | Sodium Chloride (NaCl) | Source of Sodium and Chloride ions |

| Gypsum | Calcium Sulfate (CaSO4) | Source of Calcium and Sulphate ions |

Below is a table highlighting the recommended ion profile for brewing ESB.

| Ion | Concentration in Parts Per Million (ppm) |

| Calcium (Ca2+) | 270 |

| Magnesium (Mg2+) | 41 |

| Sodium (Na+) | 113 |

| Chlorine (Cl-) | 85 |

| Sulphate (SO₄²-) | 720 |

The ion proportions above yield an ESB beer with superb clarity.

Fill your brewing kettle with water and add the appropriate water salts and potassium metabisulphite portions. Once all the salts are dissolved, you must reduce the water pH to the recommended levels (5.6-5.8). Add lactic acid until you achieve 5.6-5.8 water pH.

With all the salts added and the appropriate water pH achieved, heat the water to 152°F.

Mashing

Upon reaching a strike temperature of 152°F and within a pH range between 5.5-5.8, add your grist. For this demonstration, we’re shooting for a pre-boil gravity of 1.039. While maintaining temperatures of 152°F, let the mash cook for 60 minutes.

Use your hydrometer to monitor gravity during mashing. Take readings at 30-minute, 45-minute, and 60-minute intervals. Once you achieve a pre-boil gravity of 1.039, you can stop the mash and proceed to the next step. If you can’t achieve the gravity reading, prolong the mashing process for another 30 minutes.

After hitting a gravity of 1.039, raise mash temperatures to 168°F for the mashout step. Mashout is the process of halting enzymatic action by raising temperatures. Mashout accomplishes two things; stopping enzyme action and loosening the wort.

After 10 minutes, lift the grain bag or basket and suspend it above the brewing kettle. Spurge the grain basket with 5.6-5.8 pH water until you reach your desired original gravity.

Boiling

Extra Special Bitter beers can be pretty bitter. Style guidelines allow for upto 50 IBU. For this recipe, we’ll be shooting for about 45 IBU. And we’ll achieve that target with a combination of Fuggle hops and East Kent Goldings.

Turn up the heat to boil the wort. Lower your hop basket and add one ounce of Fuggle pellets as the wort approaches boiling. We’ll let the hops boil for 60 minutes. This treatment is sufficient to extract 33 IBU of bitterness.

We’ll add 0.5 oz East Kent Golding hops at the 20-minute mark. This addition should extract hop flavor and another 11 IBU of bitterness. Finally, add another 0.5 oz of East Kent Golding hops as you turn off the heat. Let the wort cool down to a temperature of 68°F. To expedite the cooling process, you can use a heat exchanger.

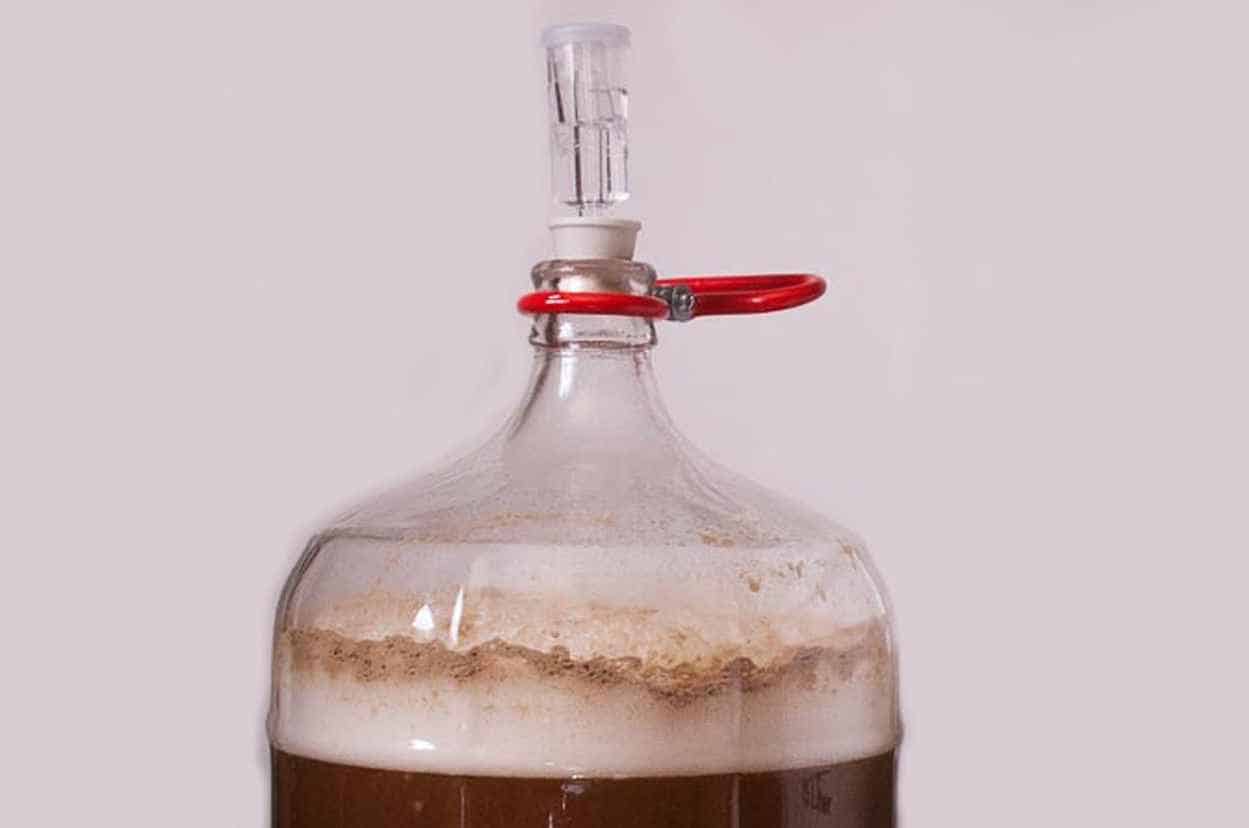

Fermentation

Transfer your wort into your fermenting vessel. Between temperatures of 66°F and 68°F, pitch your yeast. You can make a yeast starter, which involves pitching your yeast in a small amount of wort and then transferring it to the larger batch.

As fermentation nears its conclusion or five points to final gravity, add 0.5 oz of dry Kent Golding hops as you raise the temperature to 70-72°F. Steep the hops for three to five days as fermentation concludes. If there are no changes in final gravity after three days, fermentation is complete.

Packaging

Purge your kegs with carbon dioxide before racking your Extra Special Bitter (ESB) batch. Plug in your Co2 line and store the keg in a kegerator. Set the temperatures to near freezing. After one to two weeks of carbonation, the beer should be ready for consumption.

Conclusion

Congratulations, you’ve brewed your own Extra Special Bitter. Remember, the Extra Special Bitter is the strongest of the Bitter beer styles. As a British brew, it is made exclusively from English malts and hops.

How was your brewing experience? What tasting notes did you find in your beer? Please let us know in the comment section below.

As a homebrewer, Michael would get frustrated about the lack of brewing information on the internet. After hundreds of gallons of spoilt batches, Micheal had enough. And he founded Unknown Brewing as a resource for homebrewers.